2019: A Sign Odyssey/Innovation in Signage

This Saturday, we celebrate the 50th Anniversary of the Moon Landing, and as we look back at such a large milestone in science, technology, and achievement, we are reminded not only of the advancement that led to the landing, but also all the advancement we have had since then. While it may seem meek in comparison to the moon landing of all things, signage has come a long way too. Today we are going to look at the advancement and innovation of the sign making process as well as some of the technology we use along the way.

Modern technology is a driving force behind our sign making process, and factors into many aspects of signage. First, we will start with one of the most obvious technological advancements in recent decades, the internet. This not only aids internal communication between our departments, making the processes faster, but also between customers. We work with you online to send proofs, answer questions, and provide detailed information for the duration of your order. Along with the internet, programs like Adobe Illustrator, make it possible to create and share designs between clients and our separate departments, as well as input those designs into our machinery for more efficient and exact transferring.

Request a proof here!

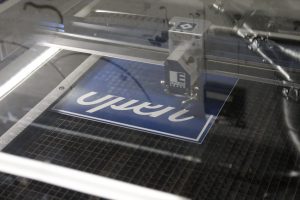

Two of the most useful technological methods we use in the sign making process, are laser engraving and routing. These allow us to quickly and precisely cut materials to exact sizes and shapes. These materials can then be assembled into what will become a sign. Laser engraving also has many capabilities for transferring designs to materials. Following the outlines and shapes specified in the design, our machinery engraves them directly into the material, removing the top layer. This results in a more permanent, high-quality, and smooth design as opposed to painting or printing, which are still very viable and beneficial options. Lasers can be used on many different materials such as metal, wood, and acrylic, and is used in a large amount of our signage.

Find Name Tags and Badges here!

Find Engraved Office Signs here!

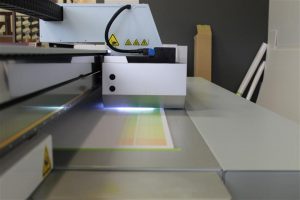

Another material we work with often is vinyl, and while it’s not as exciting as lasers, we do use some very fun machinery that prints on the vinyl, and cuts paths (designated by the programs mentioned earlier) into the vinyl. After these paths have been made (to the vinyl that is being cut), the unwanted and excess material can be removed, with the design ready to apply. This can be added on to signage, as an alternative to engraving, or applied directly to a surface such as windows or doors.

Find Vinyl Products here!

Needless to say, modern technology plays a large part in every aspect in the sign making process, from ordering and designing, to production and assembly, even to shipping. It is hard to imagine a world without what we have now, but it also exciting to imagine what technology will bring us in the future. We might even have signs in space… Still, as useful as technology can be, nothing beats that personal touch.

Written by: Jack Machacek

Contact: jackm@officesigncompany.com

www.officesigncompany.com